Lathe Risk Assessment

A comprehensive Risk Assessment for using a lathe highlights the potential risks and control measures to reduce the likelihood of injury.

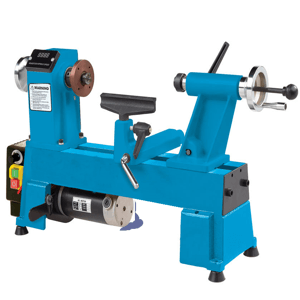

A lathe is a sophisticated machine tool designed for rotating a workpiece, enabling a cutting tool to systematically shape it into a variety of forms, predominantly cylindrical ones. This essential equipment is instrumental in the manufacturing process as it efficiently removes material to create various geometries, including but not limited to drilling, facing, knurling, and contouring. Lathes exhibit remarkable versatility, suitable for use with both wood and metal, making them invaluable across various industries, including woodworking, metalworking, automotive, and aerospace.

The operation of a lathe begins with the secure clamping of the workpiece, which is mounted on a spindle and rotated at varying speeds. As the workpiece turns, a cutting tool—either manually held or strategically mounted on the machine—is employed to remove material in a controlled manner, meticulously shaping the workpiece into the desired final form. The precision with which this material is removed allows for intricate designs and smooth finishes.

There is a diverse array of lathe types tailored to specific applications, including wood lathes for crafting decorative woodwork, metal lathes designed for machining harder materials, and CNC (Computer Numerical Control) lathes that automate the machining process for enhanced efficiency and precision. Each type of lathe is optimized for its respective materials and intended operations.

Lathes are utilized for a wide range of tasks: from the basic operations of turning and facing to more complex processes like threading and drilling. They are crucial in various applications, enabling the creation of everything from simple cylindrical objects to sophisticated, precision-engineered components.

Renowned for their accuracy, lathes can produce finished workpieces that meet high tolerances and exact specifications, making them a cornerstone in modern manufacturing and craftsmanship. Their capability to deliver consistent results over repetitive tasks underscores their significance in both small-scale workshops and large-scale industrial settings.

This document is:

- Recognised by local authorities

- Recognised by principal contractors

- Suitable for CDM sites

- Approved by H&S managers

It increases your chance of winning tenders and has been written by trained health and safety professionals.

If you want others to have confidence in your company, download and buy the proper documents today.

As with all our documents, our risk assessments are in Word™ format and available for instant download and use. You only need to buy them once.

Once you buy and download this document, it's yours for life; it's over and over again.

Download today's risk assessment, put your company details on it, and use it immediately.

Give people confidence in you, your company, your products and services.

Some sample text from this document reads:

'Injury from guard misuse'

• Operatives and others could suffer serious injury from strike and puncture wounds if guards are not used correctly

• Guards are to be inspected for damage by a competent person before use

• Guards are to be adequately secured and adjusted to correct tolerance before use

• Guards should be in place at all times to set the maximum tolerance for the operation being carried out

Why not browse the HSEDocs catalogue of method statements, risk assessments, COSHH assessments, or industry-specific packages?

GET THIS DOCUMENT

£8.99+VAT

- Available in Word™

- Fully customisable

- Add your Company Logo

- UK & EU Compliant

CART

CART