Electricians health and safety RAMs pack. BEST OFFER

All the RAMS an electrical company needs in a single comprehensive document. A complete health and safety package for just £55.00.

|

|

|

|

Sample 1 |

Sample 2 |

Sample 3 |

Electricians play a critical role in the installation, repair, and maintenance of electrical systems in both residential and commercial settings, ensuring safety and optimal functionality. They engage with various complex electrical components, including wiring, circuits, outlets, switches, and diverse lighting fixtures, tailored to meet the specific needs of each project.

In new construction or renovations, electricians install wiring and electrical fixtures according to local codes and industry standards, ensuring that each installation is safe and compliant. Their responsibilities extend beyond mere installation; they regularly perform thorough inspections and maintenance of electrical systems to guarantee efficient operation and to identify potential hazards preemptively.

Electricians skillfully diagnose and repair malfunctioning wiring, fixtures, and other electrical equipment when faced with electrical issues. Utilising their extensive knowledge and specialised tools, they quickly pinpoint the source of electrical problems, including failed fuses, overloaded circuits, or defective wiring. Their troubleshooting capabilities span a wide spectrum of electrical challenges, from straightforward fixes to more intricate system failures, while prioritising safety and cost-effectiveness.

Electricians also utilise blueprints and technical diagrams to meticulously plan electrical installations, determining the proper locations for circuits, outlets, and other vital components to ensure an efficient flow of electricity throughout the space. Their expertise encompasses a thorough understanding of both local and national electrical codes and safety regulations, ensuring that every task they undertake meets stringent compliance standards.

Moreover, electricians serve as valuable resources for homeowners and businesses, providing insightful advice on the best electrical solutions tailored to specific needs and scenarios. Seasoned electricians may also take on mentorship roles, offering training and supervision to less experienced colleagues, thereby fostering a knowledgeable workforce committed to maintaining high standards in electrical safety and efficiency.

Table of contents for the electrician package

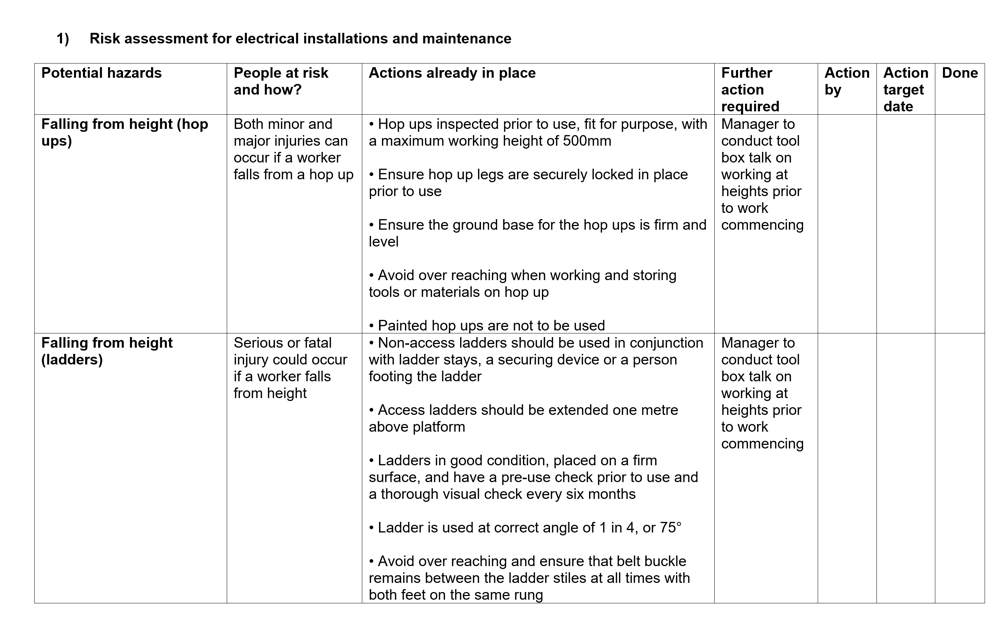

Risk assessments for:

- 01) Electrical installations and maintenance

- 02) Risk awareness for areas where asbestos could potentially be discovered

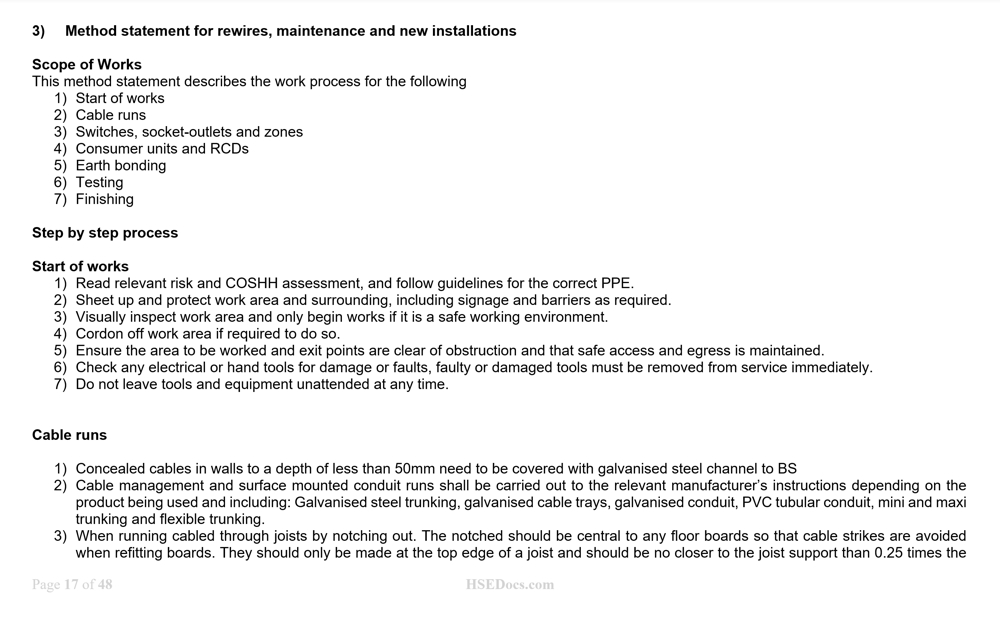

Method statements for:

- 03) Rewires, maintenance and new installations

- 04) Marking and fixing

COSHH assessments for:

- 05) Decorator’s caulk

- 06) Dust

- 07) Expanding foam

- 08) Expanding foam (fire rated)

- 09) Lead-free solder

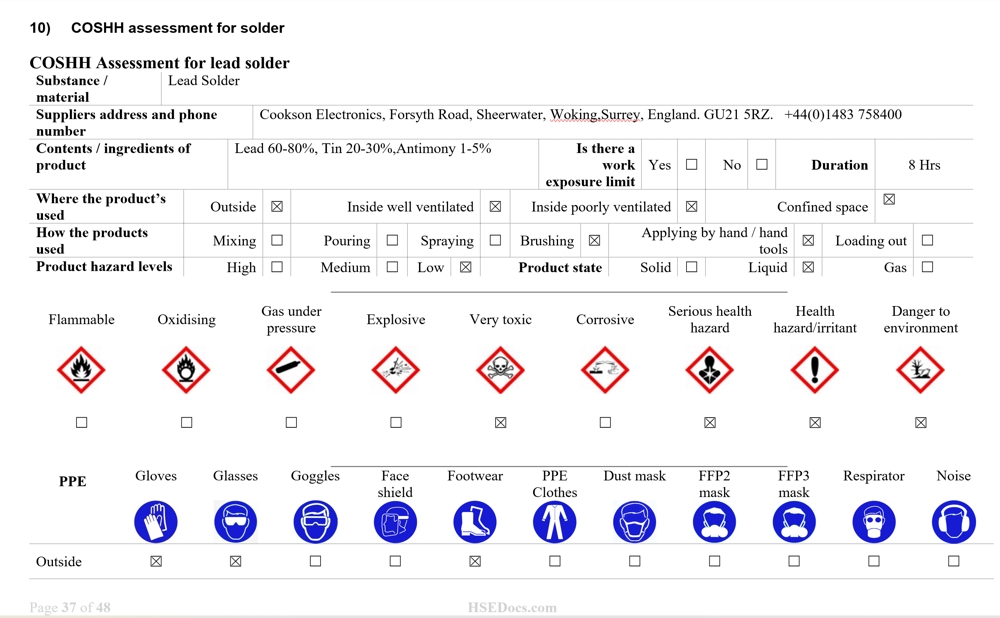

- 10) Lead solder

- 11) Silicone sealant

- 12) Soldering flux

- 13) Solvent cement

We are pleased to offer a comprehensive pack of 13 essential documents that cover various aspects of electrical health and safety. These documents have been carefully compiled based on our extensive professional experience and customers' download trends. You can instantly download and use this package, which encompasses all the necessary documents in one place.

In addition, purchasing this RAMS package will entitle you to display the prestigious "Health & Safety Gold Standard Award" on your website. This award is a testament to your current and up-to-date H&S compliance, which will reassure your clients, customers, and contractors.

We are committed to keeping your RAMS current. We regularly update this package to reflect changing H&S trends and laws. Thanks to our ongoing efforts, you can rest assured that your RAMS will always be current and compliant.

You buy the electrician's health and safety package once, and it's yours for life to download as often as you need. Each download will always be the most up-to-date version.

If you were to purchase each of these documents individually, you would have to spend a total of £115.00. However, if you were to hire a health and safety expert to create custom documents for you, the expenses would undoubtedly be much higher.

Nevertheless, price should not be the sole consideration for value for money. In this instance, you receive a customised health and safety solution for electricians. The package includes pre-completed risk assessments, method statements, and COSHH assessments.

The package is not set in stone and can be tailored to meet your specific requirements, as it is provided in docx format, which can be edited using Word™ or any other compatible software. You have the option of adding or removing sections as needed. There is also a single cover page where you can include your company's logo and information.

Electricians are skilled professionals trained to handle electricity safely and isolate electrical supplies to prevent injury. If appropriately managed, they face minimal health and safety risks. However, they still face electrical and other hazards during their normal working day. The greater risk of injury to electricians comes from accidents caused by not following safe working practices.

One of the most common causes of accidents is falls from heights involving stepladders, which can result in severe injury or even death. Overreaching, same-level slips, trips, and falls pose a significant danger. Taking shortcuts to save time and stretching off a ladder instead of using a safer position can lead to disaster, but unfortunately, some employees continue to do so repeatedly.

Moreover, some hazards may take a long time to materialise, such as asbestos-related diseases, hearing loss, and hand-arm vibration syndrome. These health issues can seriously affect electricians, making it essential to follow proper safety protocols.

The Health and Safety at Work Act requires employers to ensure the well-being of employees and anyone affected by work activities. An employer should know the risks and hazards involved and eliminate them or reduce them to an acceptable level by ensuring staff follow safe working practices. This includes educating staff on the dangers of bad working practices and repeating the same message to avoid accidents.

The demands made by principal contractors and CDM sites for H&S compliance are an ever-growing list. Method statements are not a legal requirement, but very few large sites will get a company on their approved supplier list without them. Principal contractors may also request a host of other documentation that is not a legal requirement, such as training records, traffic management plans, anti-slavery policies, etc…

Additionally, H&S documentation may be required on a task basis, such as permits to work in confined spaces, for hot works, or at heights.

As a general rule, though the four primary documents you need are:

A company health and safety policy. This document lets others know how your business manages health and safety at work. It is a legal requirement to have a health and safety policy if there are five or more employees, and usually a requirement for site work regardless of business size.

Risk assessments. Their purpose is to identify hazards and introduce control measures and safe working practices to eliminate them or bring them down to an acceptable level.

Method statements. Method statements are not a legal requirement. However, most businesses' best practice is to inform staff and principal contractors of their company's methods to carry out tasks safely.

COSHH assessments. These are hazards that specific products pose, and they don’t just cover the health of the person using the product. The damage the product can do to the environment, safe disposal methods, amount of time a person can work with the product, fire fighting measures, harmful ingredients, PPE and first aid measures are all included.

The electrical health and safety package we’ve put together covers all of the above except the company policy, as this is a stand-alone document.

Authoring a book that never sees the light of day is futile, as no one will ever have the opportunity to read and appreciate its contents. Similarly, with health and safety (H&S) documents, it is not enough for a company manager to provide another manager with an H&S package that meets all the necessary criteria. The knowledge and understanding of safe working practices must be communicated effectively to the staff carrying out the work.

While training, education and instruction can take many forms, the ultimate goal of H&S is to convey a message clearly and effectively. For example, when using ladders safely, staff may be given pictorial fliers that demonstrate safe use, observe someone giving a demonstration, or attend a comprehensive working-at-height course.

However, training alone is often insufficient to ensure the safety of a workforce, and managers typically need to reiterate the same message multiple times to reinforce safe working practices. It is not just about the training itself but also about ensuring it is followed. With the advent of online courses, training has become much easier to manage and more cost-effective, and the construction industry has identified four courses as essential.

These courses are:

- Slips, trips and falls.

- Working at height.

- Manual handling.

- Asbestos awareness.

GET THIS DOCUMENT

£55.00+VAT

- Available in Word™

- Fully customisable

- Add your Company Logo

- UK & EU Compliant

CART

CART