Ceramic Tilers health and safety RAMs pack. BEST OFFER

Kitchens, bathrooms, saunas or swimming pools. These are the RAMS you need. A complete H&S package for just £65.00

|

|

|

|

Sample 1 |

Sample 2 |

Sample 3 |

What are RAMS for ceramic tilers?

RAMS for ceramic tilers are established to ensure the safety of workers and others who may be affected by their work. But what risks do ceramic tilers encounter during their careers? Some of these risks include:

Cuts and Puncture Wounds: Ceramic materials are particularly hazardous when they break, as they shatter into sharp fragments that pose a significant risk of cuts and abrasions to the hands. The inherent fragility of ceramic means that during the process of snapping or cutting tiles, sharp shards can be violently ejected, leading to potential strike injuries to the eyes and facial injuries.

Falls From Height: Falls from height represent a frequent and serious risk in the construction industry, typically involving the use of step ladders, toolboxes, or portable platforms (“hop-ups”). These accidents can be exacerbated by the surrounding work environment, particularly if the floor surface becomes wet, contributing to same-level slips, trips, and falls.

Electric Shocks: This hazard significantly increases when work is performed without properly isolating the electrical supply. Even in cases where isolation is believed to have been achieved, there remains a danger that cables can become loose or exposed when installing tiles around electrical outlets and switches.

Manual Handling Injuries: The physical demands of manual handling, repetitive tasks, and working in confined spaces can lead to musculoskeletal injuries, including strains and chronic pain conditions. Furthermore, occupational hazards extend to skin exposure; tile adhesive can cause contact dermatitis and other skin-related ailments when it comes into contact with the skin.

Asbestos Related Illnesses: For properties built prior to the year 2000, there exists a perpetual risk of accidental asbestos disturbance. Engaging in renovations or alterations in such structures can inadvertently release asbestos fibres, which are known to cause serious health issues, including various forms of cancer and other debilitating diseases. Awareness and adherence to safety regulations regarding asbestos management are crucial in mitigating these risks.

What are RAMS?

Because of the risks involved with ceramic tiling and the general work environment, RAMS are put in place to mitigate the risks and make tasks safer to perform. RAMS are Risk Assessments, Method Statements and COSHH Assessments, and each one serves a different purpose.

Here’s a breakdown of each document:

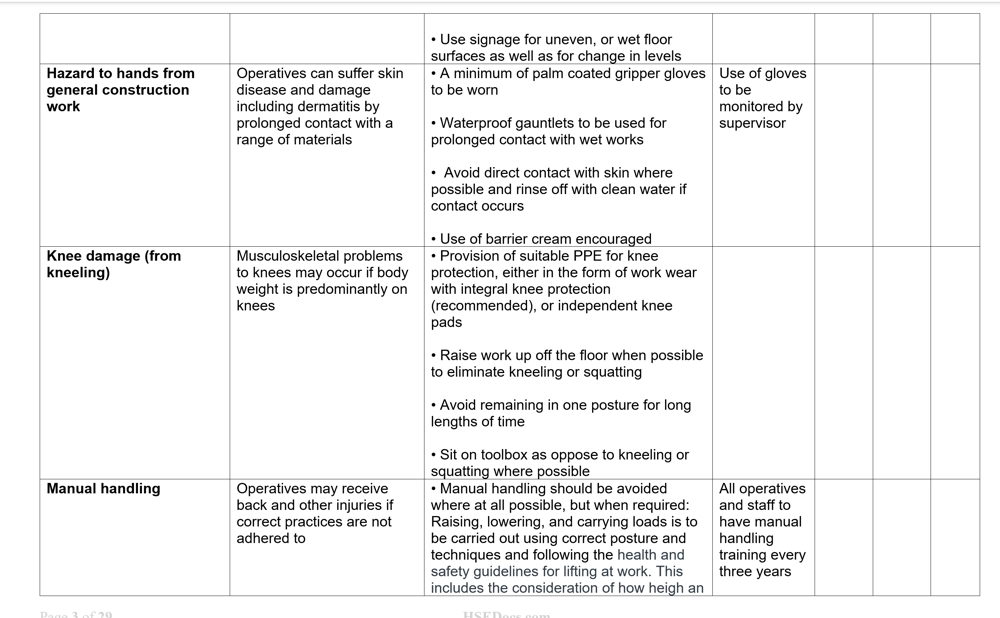

Risk Assessments: A ceramic tiler's risk assessment is a document that identifies potential hazards during tiling work, evaluates their severity and likelihood, and outlines control measures to reduce risks to an acceptable level, thereby protecting people, the environment, and the business. It addresses hazards such as cuts from sharp tiles, falls, dust inhalation from cutting, musculoskeletal problems caused by manual handling, and skin irritation from adhesives, as well as electrical risks and possible asbestos exposure. The assessment ensures compliance with health and safety regulations by providing clear actions and controls for a safer working environment.

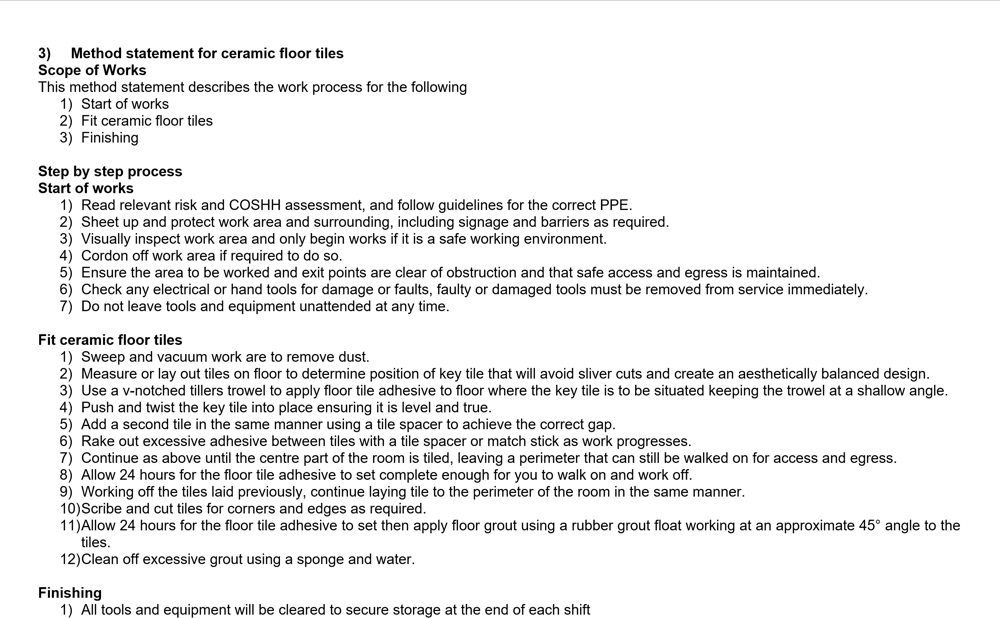

Method Statements: A ceramic tile method statement is a detailed document that outlines the step-by-step procedures for installing ceramic tiles, including preparatory works, materials handling, tile laying, grouting, cleaning, and safety measures. It acts as a comprehensive instruction manual for workers and a checklist for quality control, defining roles, responsibilities, equipment, and potential hazards to ensure the work is completed correctly, safely, and to the project's specifications.

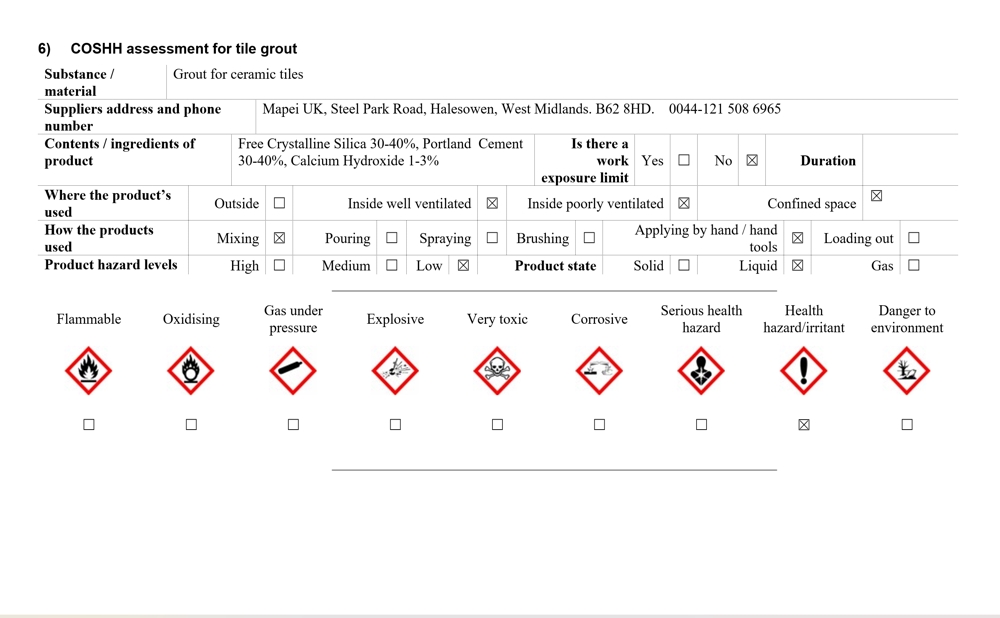

COSHH Assessments: A COSHH assessment for ceramic tiles involves a formal risk evaluation process to identify and control health hazards from hazardous substances, including dust created during cutting, potential skin or eye contact with grout, and any chemicals in adhesives or sealants used. This process, required by law, ensures employers protect workers by recognising hazards, assessing risks, and implementing control measures such as dust suppression, personal protective equipment (PPE), and proper disposal procedures.

GET THIS DOCUMENT

£65.00+VAT

- Available in Word™

- Fully customisable

- Add your Company Logo

- UK & EU Compliant

CART

CART