Construction company, health and safety RAMs pack. BEST OFFER

All the RAMs a construction company needs in one simple-to-use document.

|

|

|

|

Sample 1 |

Sample 2 |

Sample 3 |

Construction companies play a vital role in the development and upkeep of a wide array of structures, from residential homes to complex industrial facilities and critical infrastructure like highways and bridges. These firms oversee projects through every phase, starting with initial planning and design, continuing through the construction process, and finally completing the project.

Their responsibilities encompass a comprehensive suite of services, including architectural design, project management, renovation, repair, and ongoing maintenance. Each project is tailored to meet specific requirements, ensuring that structures meet aesthetic and functional standards and comply with safety regulations and building codes.

In addition to constructing new buildings, construction companies often undertake significant renovations, adapting existing structures to meet modern needs or to enhance their lifespan. They also provide maintenance services, ensuring that infrastructure like roads, bridges, and airports remains safe and operational.

Specialisation within the construction industry is common, with certain companies focusing on niche areas such as residential construction, commercial projects, or large-scale industrial endeavours. Additionally, some companies may concentrate on specific types of structures, like skyscrapers or renewable energy installations, allowing them to leverage expertise in those fields.

Effective resource management is critical to the success of any construction project. Companies meticulously oversee allocating and using labour, materials, and equipment to ensure timelines are met and budgets are followed, all while maintaining a high-quality standard. Coordinating these resources efficiently is essential to navigating the complexities of construction and delivering successful outcomes.

Table of contents for construction package

Risk assessments for:

- 01) 1st and 2nd fix carpentry works

- 02) 1st and 2nd fix plumbing and gas works

- 03) 80 and 360 excavators

- 04) Brick and blockwork

- 05) Ceramic tiling

- 06) Cleaning

- 07) Construction workers

- 08) Electrical installations and maintenance

- 09) External painting and decorating works

- 10) General groundworks and fencing

- 11) Internal painting and decorating works

- 12) Plastering and rendering

- 13) Pressure washing

- 14) UPVC doors, windows, soffits and fascia

- 15) Electrical testing

- 16) Risk awareness for areas where asbestos could potentially be discovered

Method statements for:

- 17) Block paving

- 18) Boarding and skimming

- 19) Bonding and skimming

- 20) Brick and blockwork

- 21) Builders and office clean

- 22) Ceramic floor tiles

- 23) Ceramic wall tiles

- 24) Cleaning brickwork

- 25) Connection or alteration to gas main

- 26) Electrical testing

- 27) Fencing

- 28) Fitting a bathroom suite

- 29) General plumbing works, pipe connections, transport and storage

- 30) Hacking off to walls and ceilings

- 31) Hanging doors

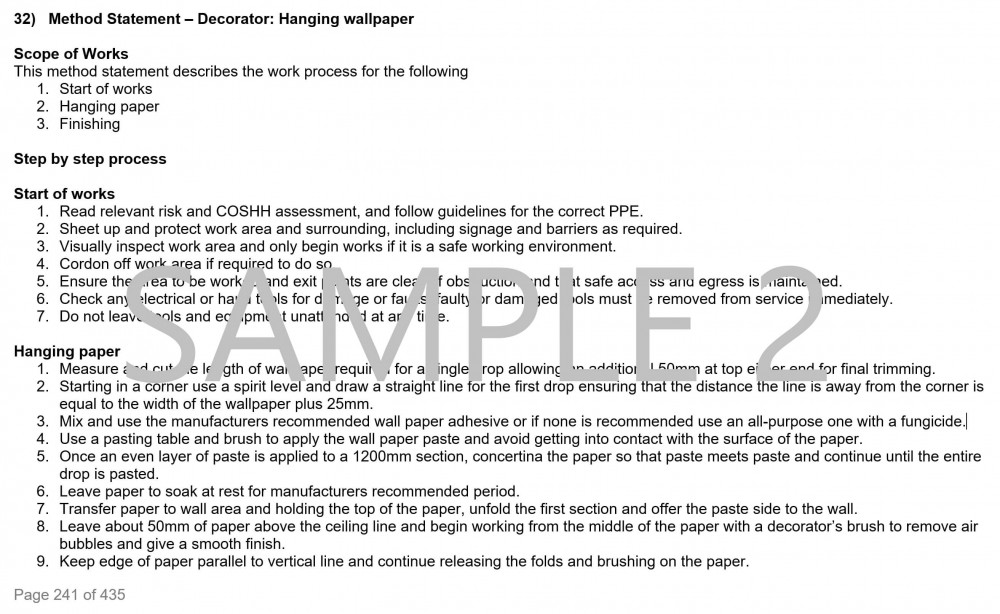

- 32) Hanging wallpaper

- 33) Kitchen fitting

- 34) Laminate flooring

- 35) Laying slabs

- 36) Maintenance and service of central heating system

- 37) Marking and fixing

- 38) Painting

- 39) Pointing and repointing

- 40) Power flushing

- 41) Pressure washing

- 42) Rainwater goods

- 43) Removing a bathroom suite

- 44) Rendering

- 45) Rewires, maintenance and new installations

- 46) Roof timbers

- 47) Timber partitioning

- 48) Underground drainage

- 49) Underpinning

- 50) UPVC doors

- 51) UPVC soffits and fascia

- 52) UPVC windows

COSHH assessments for:

- 53) Bleach

- 54) Bonding coat

- 55) Brick and patio cleaner - Acid

- 56) Brick and patio cleaner - Eco

- 57) Carpet cleaner

- 58) Cement

- 59) Contact adhesive

- 60) Cream cleaner

- 61) Decorator's caulk

- 62) Detergent

- 63) Disinfectant

- 64) Dry wall adhesive

- 65) Dust

- 66) Eggshell finished paint oil based

- 67) Expanding foam

- 68) Expanding foam (fire rated)

- 69) Exterior undercoat oil based

- 70) Fernox central heating cleaner

- 71) Flux paste

- 72) Furniture polish

- 73) Glass cleaner

- 74) High gloss oil based

- 75) Hydrated lime

- 76) Hydraulic lime

- 77) Intumescent sealant

- 78) Latex screed

- 79) Lead free solder

- 80) Lead solder

- 81) Metal primer zinc phosphate

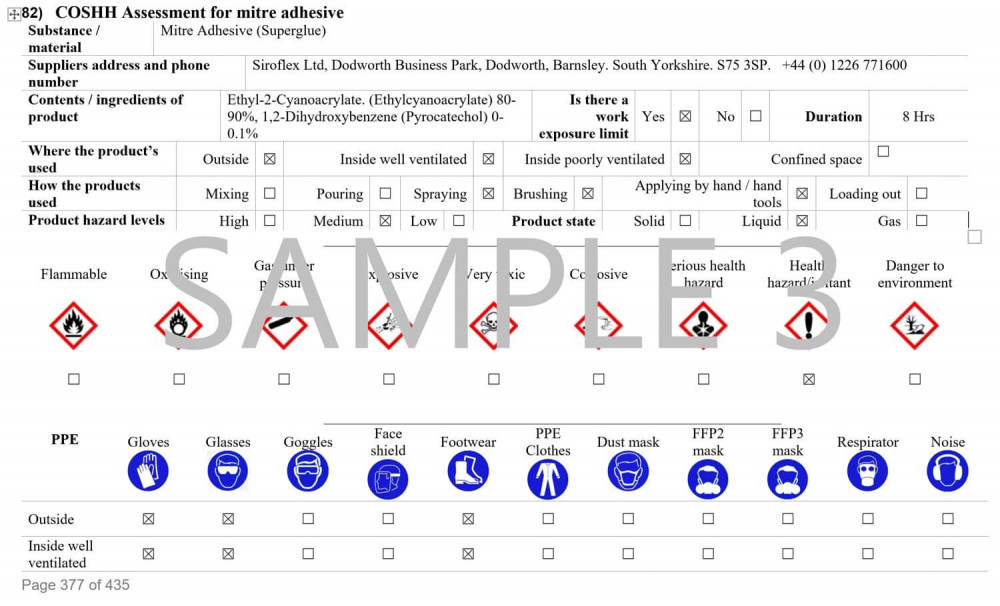

- 82) Mitre adhesive

- 83) Mitre adhesive activator

- 84) Mortar plasticiser

- 85) Mortar water proofer

- 86) MultiFinish

- 87) Multi surface cleaner

- 88) Petrol

- 89) PVA

- 90) Quick drying gloss water based

- 91) Quick drying primer and undercoat water based

- 92) Silicone sealant

- 93) Solvent cement

- 94) Solvent cleaner

- 95) Solvent-free grab adhesive

- 96) Tanking slurry

- 97) Thinners

- 98) Tile adhesive

- 99) Tile grout

- 100) White spirit

The main benefits of our construction health and safety package include:

- An incredible 100 documents - Creating a comprehensive construction health and safety package suitable for most construction companies

- User Friendly - The construction health and safety pack has been designed for ease of use with a cover page, so there’s no need to scroll through the entire document to edit things like dates and signatures. The cover page is designed for you to add your company logo, name of the person responsible for H&S, sign, and date, and then you’re good to go.

- Reliability - This package has been assembled based on our professional experience, customer input, and download trends. Accessibility - Our construction health and safety document is in docx format. This means it can be opened in Word™ or any other word processor and is fully editable. Once you buy this package, it becomes yours to edit as you please.

- Award - As a bonus, this package allows you to display the "Health & Safety Gold Standard Award" on your website. This lets clients, customers, and contractors know that your company’s H&S package is current and up to date.

- Stands the test of time - Your construction health and safety documents will be current and up to date and will stay that way. As H&S changes, we update this construction company package to reflect new trends and laws.

Here at HSEDocs, we are committed to upholding positive values that prioritise the needs of our clients and their businesses. We take pride in offering top-quality training courses and health and safety documents that provide exceptional value for money. Our construction health and safety pack is a prime example of this commitment to excellence, as it offers incredible savings of up to £582.00 compared to purchasing the same documents individually. With this pack, you can rest easy knowing that you are getting the best value for your money while ensuring the safety of your construction company. Additionally, the package is:

Additionally, the package is:

- Recognised by local authorities.

- Recognised by principal contractors.

- Suitable for CDM sites.

- Approved by H&S managers.

In the highly competitive construction industry, winning tenders can be daunting. However, with the H&S Pack from HSEDocs, you can gain a significant edge over your competitors. A comprehensive and professional approach to projects instils trust and confidence in your company and empowers you to stand out and win tenders with ease. This advantage is highly sought-after by project managers and supply chain decision-makers, making your success more attainable.

Health and Safety regulations are not just a legal requirement but a crucial tool to protect individuals in various settings. Everyone's safety is at stake, from permanent employees to casual workers, the self-employed, and even visitors like delivery personnel. In today's world, businesses are responsible not only for the safety and well-being of their employees but also for anyone affected by their activities or premises. It is, therefore, of utmost importance that businesses take this responsibility seriously and ensure that their operations do not cause harm to others.

The construction industry, in particular, is a high-risk sector, with a staggering 50,000 injuries and an average of 30 fatalities reported annually. These figures, mind you, are with the current health and safety measures in place. Yet, they are still alarmingly high, indicating a pressing need for better health and safety management to reduce these numbers significantly. As a result, risk assessments, method statements, and COSHH assessments have become standard practice, even in small companies.

Falls from height account for approximately half of all fatalities, and a breakdown of the 50,000 non-fatal injuries is as follows:

- Slips, trips and falls on the same level account for 25%.

- Falls from height account for 18%.

- Manual handling injuries make up 20%.

- Being struck by a moving or flying object is 10%.

It’s important to remember that the 50,000 number of reported injuries is much lower than the accident rate. This is because many people can slip or fall without injury.

What Health and Safety Does a Construction Company Need?

All employers are responsible for the safety and well-being of their employees and anyone affected by their business activities or premises. Occupational health and safety rules and regulations apply to all industries, but the construction industry has the most stringent requirements. The safety measures that companies need to follow change depending on the type of work they are involved in. For example, certain employees may require permits to work in confined spaces, perform hot works, or work at heights. Other employees may need to ensure the scaffolds are approved or carry out CAT and Genny tests before digging.

As a general rule, though, the four primary documents you need are:

- A company health and safety policy - A health and safety policy document is a crucial tool that outlines how your business manages health and safety at the workplace. It is mandatory to have this policy in place if five or more employees are working for your organisation. The document should provide a clear and comprehensive overview of the procedures and measures your business has in place to ensure the safety and well-being of everyone in the workplace. By having a well-crafted health and safety policy, you can demonstrate your commitment to maintaining a safe work environment for your employees while complying with the legal requirements.

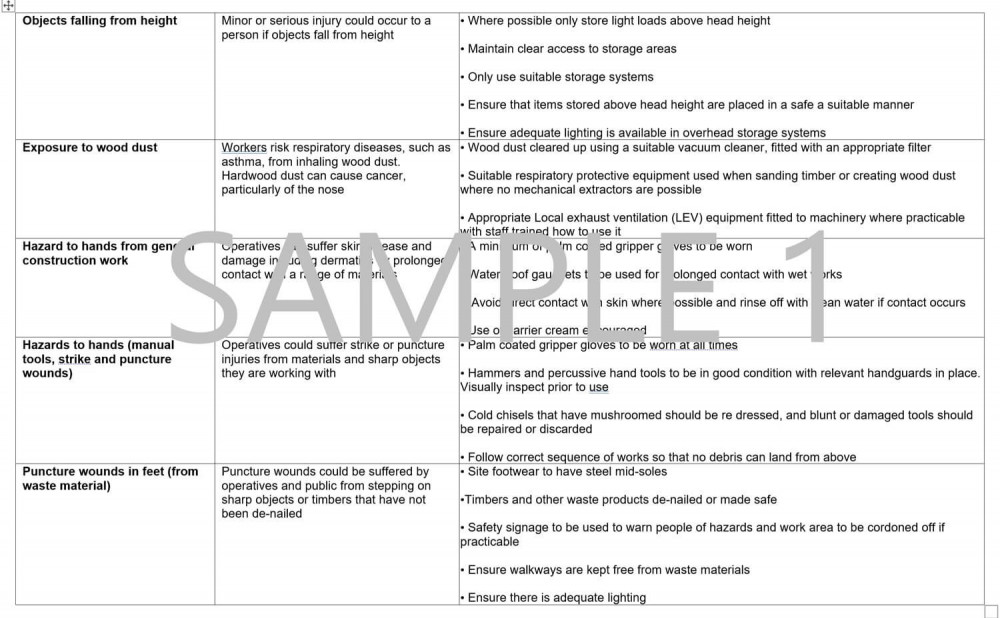

- Risk assessments - Risk assessments are crucial for ensuring the safety of individuals while performing a task. They assess the potential risks involved in the task and provide necessary control measures to mitigate those risks. Control measures guide individuals in performing the task safely and avoiding any possible harm. These instructions are critical in reducing the likelihood of accidents and ensuring a safer work environment for all.

- Method statements - The process of assembling furniture can be daunting for many people, especially if they are unfamiliar with the language used in the instructions. However, Ikea has mastered making it easier for everyone by providing instruction manuals suitable for all language speakers. These manuals incorporate visual cues like ticks and crosses that guide the assembler on what to do and what not to do, making it more straightforward to understand the process.

Similarly, in the construction industry, method statements ensure workers carry out their tasks safely. Although these statements are usually text-based, they are designed to provide step-by-step guidance on completing a task without compromising safety. In some cases, suppliers may offer method statements to guide workers on installing specific items like locks, and it is recommended to follow the manufacturer's instructions to ensure that the task is completed accurately and safely. - COSHH assessments - When dealing with certain products, being aware of their risks is essential. To assess these risks, a COSHH (Control Of Substances Harmful to Health) assessment is created using the product data-sheet provided by the supplier. However, the COSHH assessment is not just concerned with the health of the person using the product. It considers various factors, such as the product's potential environmental impact, safe disposal methods, recommended usage time, firefighting measures, harmful ingredients, personal protective equipment (PPE), and first aid measures. Considering all of these factors, the COSHH assessment helps ensure that the product is used safely and responsibly.

• Principal contractors and project managers may also ask you for other documentation, including training records, traffic management plans, anti-slavery policies, etc.…

Working on a construction site can be a risky and potentially hazardous occupation. In addition to investing in a comprehensive health and safety package, adhering to a set of site rules is crucial to ensure your colleagues and your safety. By following these safety protocols, you can mitigate the risks and prevent accidents from occurring on the job.

The HSDocs Health and Safety Packs are tailored to aid you in effectively managing and communicating workplace hazards to your staff. By following the correct working practices and mitigating risks by removing hazards proactively, you can ensure a safe and secure work environment for your team.

Many construction workers are injured yearly while working on UK building sites due to slips and trips. Shockingly, almost 1,000 of these injuries involve bone fractures or joint dislocations. However, most of these injuries can be avoided by following good working practices, such as ensuring the effective management of work areas and access routes like footpaths, stairwells, corridors, and site cabins.

There can be many other reasons for a slip, trip, or fall at work, or other accidents at work, yet none of these is the result of a deliberate act of sabotage; it's just poor H&S.

GET THIS DOCUMENT

£245.00+VAT

- Available in Word™

- Fully customisable

- Add your Company Logo

- UK & EU Compliant

CART

CART